International Steel Span Factory

We have over 50 years of proven methods that have been tested and retested in markets across the globe. The International Steel Span manufacturing process is simple, effective and ultra productive. Our techniques are world-class and our products surpass even the most rigorous quality standards in any production environment. |

|

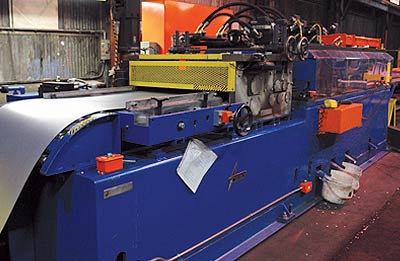

Roof and Sidewall Panel Line |

|

Steel coils are placed on a mandrel. |

The steel is leveled through a straightener. |

The steel is then punched by a state-of-the-art punching system. |

The steel is cut to length. |

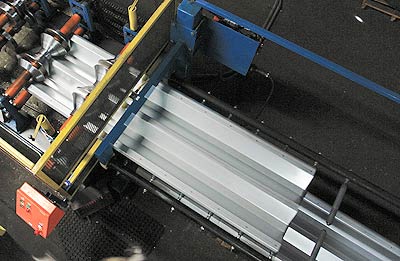

The cut sheets are shaped trhough a roll-forming process. |

The finished product is auto-stacked. |

In the straight form, each panel is used for the sidewall of each building style and model. The same panel is also used for all the roof systems we manufacture, by simply applying a radius through a crimping process illustrated in the next step. |

|

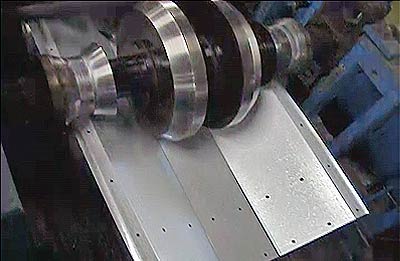

Crimping the Panel |

|

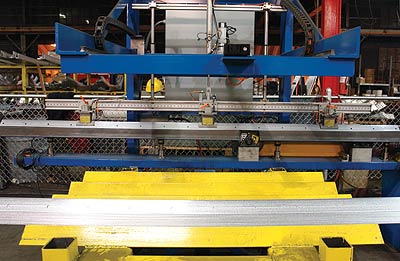

The finished roof panel is automatically loaded onto a conveyor which moves the panel into the crimping machine. |

The panel is fed from the conveyor into the crimping machine where a radius is applied. |

The finished panel is transferred by a robotic arm onto a pallet ready for shipment. |

|

Endwall Panel Line |

|

Steel coils are placed on a mandrel. |

The steel is leveled through a straightener. |

The steel is then punched by a state-of-the-art punching system. |

The steel is cut to length. |

The cut sheets are shaped through a roll-forming process |

The finished product is auto-stacked. |

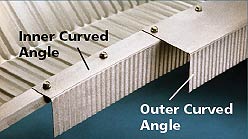

Curved Angle Line |

|

This two-part system becomes the universal efficient connection-point, which joins the endwall system to the roof and sidewall system. |

|

Steel coils are placed on a mandrel. |

The steel is leveled through a straightener and punched by a state-of-the-art punching system. |

The steel is cut to length. |

The cut sheets are shaped through a roll-forming process. |

The semi-finished part is auto-stacked. |

The semi-finished part from the previous step is then completed through a curving process. |

©2010 - 2014 King Solomon Creative Enterprises Corp.